2.5 TECHNICAL DATA PACKAGE (TDP) DRAWING/MODEL ELEMENTS.

2.5.1 TDP Elements. TDPs shall consist of one or more of the following TDP elements as specified on the contract or purchase order.

2.5.1.1 TPD DI-SESS-81001C Conceptual Design Drawings and Models. These drawings and models shall be legible and appropriate for the mode of presentation. Sketches, layout drawings and combinations of types of engineering drawings may be used to convey the engineering concept in such a manner that the engineering information is understandable to cognizant engineers and scientists. Unless otherwise specified, the requirements of ASME Y14.100 including Appendices A thru E do not apply. (Formerly LEVEL 1 of DOD-D-1000.)

2.5.1.2 TPDTPD DI-SESS-81002D Developmental Design Drawings, Models and Associated Lists. These drawings, models and associated lists shall include, as applicable, parts lists, detail and assembly drawings, models, interface control data, logic diagrams, schematics, performance characteristics, critical manufacturing limits, and details of new materials and processes. Special inspection and test requirements necessary to determine compliance with requirements for the item shall be defined on the engineering drawings directly or by

reference. If required by the TDP Option Selection Worksheet, contract or purchase order, developmental design drawings, models and associated lists shall be prepared in accordance with ASME Y14.100 and the appropriate Appendices A thru E. (Formerly LEVEL 2 of DOD-D-1000.)

2.5.1.3 TPD DI-SESS-81000C Product Drawings, Models and Associated Lists. These selected engineering drawing types shall include: details of unique processes when they are essential to design and manufacturing; detailed performance ratings; dimensional and tolerance data; critical manufacturing assembly sequences; tolerance input and output parameters; schematics; mechanical and electrical connections; physical characteristics, including form and finishes; details of material identification; inspection, test and evaluation criteria; necessary calibration information and quality control data to enable the procurement or manufacture of an item essentially identical to the original item. Product drawings and associated lists shall be prepared in accordance with ASME Y14.100 and the appropriate Appendices A thru E in conjunction with ASME Y14.24, ASME Y14.34M and ASME Y14.35M, unless these requirements are not included in the TDP Options Worksheet, contract or purchase order. Models shall be prepared in accordance with MIL-DTL-31000C and ASME Y14.41. (Formerly Level 3 of DOD-D-1000.)

2.5.1.4 TPD DI-SESS-81003C Commercial Drawings, Models and Associated Lists. Commercial drawings, models and associated lists shall provide engineering and technical information in support of end products, or designated portions thereof, which are commercially developed items, commercial off-the-shelf items (COTS), or items not developed at government expense. These drawings, models and lists are prepared in accordance with the commercial design documentation practices of the contractor or supplier of the item.

2.5.1.5 TPD DI-SESS-81004C Special Inspection Equipment (SIE) Drawings, Models and Associated Lists. SIE drawings, models and associated lists shall be prepared to provide the data required to permit the limited production of SIE which duplicates the physical and performance characteristics of the original SIE. SIE is also

known as Special Test Equipment (STE).

2.5.1.6 TPD DI-SESS-81008C Special Tooling Drawings, Models and Associated Lists. Special tooling drawings, models and associated lists shall be prepared to provide the data required to manufacture special tooling which is mandatory to successfully produce the item. The special tooling shall be defined in detail to the extent necessary for a competent manufacturer to produce tooling which duplicates the performance characteristics of the original tooling.

2.5.1.7 Appropriate DID Listed for the Preparation of Military Specifications as Required in the Contract or Purchase Order. (See TABLE 2-6, Note 1.) These specifications shall be prepared as performance, detailed and program-unique specifications as required in the contract or purchase order. Included are fully coordinated, limited coordination or "USED IN LIEU OF" military specifications in accordance with MIL-STD-961.

2.5.1.7.1 Commercial Item Descriptions (CIDs). CIDs shall be prepared in accordance with Federal Standardization Manual to describe, by functional, performance, or essential physical requirements, available commercial products or services.

2.5.1.8 Appropriate DID Listed for the Preparation of Drawings, Models and Associated Lists for Preservation, Packaging, Packing and Marking Data. (See TABLE 2-3, Note 3.) Preservation, packaging, packing, and marking requirements for hardware shall be documented for each end item and repair accordance with MIL-STD-2073-1. Detailed drawings, models and associated lists required to describe packaging requirements shall be prepared as product or commercial drawings, models and associated lists whichever was ordered for the item under contract.

2.5.1.9 Appropriate DID Listed for the Documentation of Software. (See TABLE 2-3, Note 4) Software and software documentation required for the operation of the hardware defined in the TDP shall be prepared in accordance with MIL-DTL-31000C, IEEE 12207.0, IEEE 12207.1 and IEEE 12207.2. (Formerly MIL-STD-498.)

2.5.1.10 Special Packaging Instructions Drawings/Models. (New in MIL-DTL-31000C) Special packaging instructions drawings/models shall be prepared to provide the data required to manufacture special packaging which is mandatory to successfully produce and transport the item.

2.5.2 Conditions Required for Preparing Developmental and Production Drawings, Models and Associated Lists. The following conditions for the preparation of engineering drawings, models and associated lists for Development and Production shall be governed by the contract or purchase order citing the appropriate DIDs and “TDP Option Selection Worksheets”.

2.5.2.1 Application of the Metric System. When the metric system (SI) is specified in the contract or purchase order for new design, TDP documents shall be identified as metric documents and conform to FED-STD- 376.

2.5.2.1.1 Metric Values. Metric values, when used on engineering drawings, shall be in accordance with ASTM SI 10 (X-Ref: IEEE SI 10). (Formerly ASTM E 280.)

2.5.2.2 CAGE Assignment Number Placement. If a Government Design Activity or Contractor Design Activity is named, the Commercial and Government Entity (CAGE) code and drawing number will be placed in the title block of each engineering drawing and its associated list and on each model as defined in ASME Y14.41 and SECTION 26 of the DRM. References on existing documents or preprinted document forms using the terms “FSCM” or Code Ident.” need not be revised for the sole purpose of conversion to “CAGEC or “CAGE Code”. Such conversion may be made concurrently with other needed changes.

2.5.2.3 Design Activity Assignment Identification. When Government Design Activity drawing numbers are to be assigned, drawings must identify the assigning activity and if government drawing formats are to be supplied, drawings must identify the source.

2.5.2.4 Associated Lists. Specify the kinds of associated lists required.

2.5.2.5 Associated Lists Assembly Level. Specify the drawing assembly level at which associated lists will be prepared.

2.5.2.6 Selection of Drawing System. States whether the mono- or multi-detail drawing system will be used.

2.5.2.7 Placement of Parts Lists. Specify if parts lists shall be integral with, or separate from, the engineering drawing or model.

2.5.2.8 Drawing and Model Format. The number and types of drawings, models and associated lists should be kept to a minimum. As the complexity of the item increases, different types of engineering drawings providing additional engineering description and controls may be required by the procuring activity, contract or purchase order.

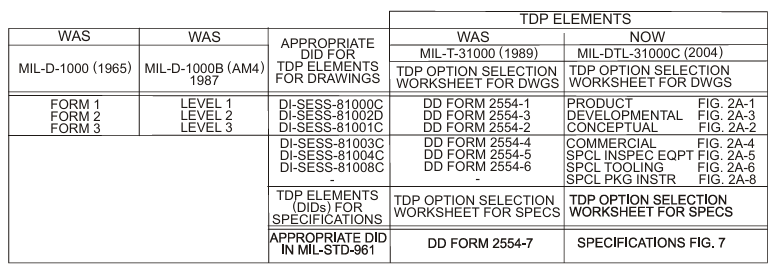

2.5.3 Technical Data Package (TDP) Drawings/Models in Relation to Previous Drawing Forms. Comparison of the current MIL-DTL-31000, the former MIL-T-31000, DOD-D-1000B (AM4) and the "NO" revision MIL-D-1000 (1965). (See TABLE 2-2.)

Table 2-2

2.5.4 Verifying the Use of TDP Drawing/Model Elements. Inspection of TDP Drawing/Model elements including TDP documents prepared by subcontractors, shall be inspected for the following:

- Compliance with the requirements of MIL-DTL-31000 and applicable Data Item Descriptions (DIDs) as tailored in the contract or purchase order.

- Inclusion of all documents, including sub-tier references, required to meet the information content requirements of the TDP element except Acquisition Streamlining and Standardization Information System (ASSIST Database) and Non-Government Standardization (NGS) documents.

- Accuracy of the assignment and identification of security markings, distribution statements, export control notices, rights-in-data legends and other special markings.

- Inclusion of contract numbers and contractor identifications.

- Legibility and reproducibility.

- TDP components have not been prepared for requirements which could be met by existing standardization documents except as permitted for commercial drawings, models and associated lists.

- References to other standardization documents, Government or non-Government, listed in the ASSIST DATABASE shall not be prepared or submitted as part of the TDP unless it is necessary to specify variations necessary to fulfill the design or performance requirements.

- Completeness and accuracy of the TDP documents, including required quality assurance information, in describing the design of the item, its subassemblies, and component parts. When the Government has approved, tested or accepted a configuration of the item that is the design to be described by the TDP documents.

2.5.5 Technical Data Package (TDP) Elements for Drawings and Models with Reference to Supporting Documents. The contract or purchase order containing the Statement of Work (SOW) will cite the appropriate DIDs on the Contract Data Requirements List (CDRL) DD FORM 1423 (See APPENDIX A FIGURE 2A-9) for selecting TDP Elements for preparing drawings, models and specifications. Included will be the appropriate TDP Option Selection Worksheet, FIGURES 2A-1 through 2A-8a, for determining what technical data is being acquired. See TABLE 2-3.

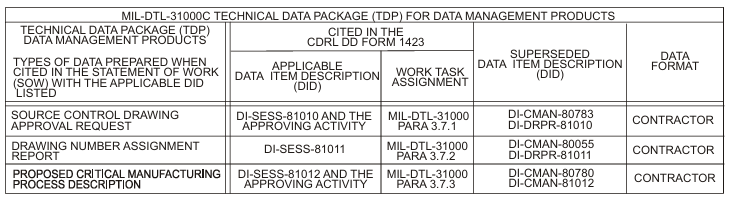

2.5.6 Conditions Required for Preparing TDP Data Management Products. When specified in the contract or purchase order, the following data products related to the management and control of TDPs shall be prepared. Only the TDP data management products that are listed on the Contract Data Requirements List (CDRL), DD FORM 1423 of the contract or purchase order are required to be delivered to the Government.

2.5.6.1 Source Control Drawing Approval Request. Source Control Drawing (SOCD) approval requests shall be prepared and submitted to the cognizant Government activity specified in the contract or purchase order as having approval authority. Each potential source control item shall be approved by the Government activity having source control drawing approval authority prior to including of the source control drawing in the TDP.

2.5.6.2 Drawing Number Assignment Report. A drawing number assignment report shall be prepared to identify and describe the use of Government drawing numbers by the contractor per DI-SESS-81011C.

2.5.6.3 Proposed Critical Manufacturing Process Description. Proposed critical manufacturing process descriptions shall be prepared to describe manufacturing processes which are critical to meeting the design requirements of the item per DI-SESS-81012C. The process shall be approved as critical by the Government activity cited in the contract or purchase order as having approval authority before it is designated as mandatory in TDP documents.

2.5.7 Verifying the Use of TDP Data Management Products. Inspection of TDP Data Management Products and the components thereof, including documents prepared by subcontractors, shall be inspected for the following:

- Compliance with the requirements of MIL-DTL-31000 and applicable Data Item Descriptions (DIDs) as tailored in the contract or purchase order.

- Inclusion of all documents, including sub-tier references, required to meet the information disclosure requirements of the TDP Data Management Product.

- Accuracy of the assignment and identification of security markings, distribution statements, export control notices, right-in-data legends, and other special markings.

- Inclusion of contract numbers and contractor identifications, when applicable.

- Legibility and reproducibility.

2.5.8 Technical Data Package (TDP) Data Management Products with Reference to Supporting Documents The contract or purchase order containing the Statement of Work (SOW) will cite the appropriate DIDs on the Contract Data Requirements List (CDRL). (DD FORM 1423) (See APPENDIX A FIGURE 2A-9) for selecting TDP Management Data Products for preparing what types of data is being acquired. (See TABLE 2-4.)

NOTE: Unless otherwise specified, Technical Data Package (TDP) Data Management Products require “DISTRIBUTION STATEMENT” notations applied to the document.

Table 2-4