PREFACE 1

FURTHER CHANGES IN ACQUISITION REFORM:

ELIMINATION OF THE WAIVER REQUIREMENT

TO USE MIL-SPECS AND MIL-STDS

1998 – Acquisition Reform:

One of the major emphases added to the 10th edition was related to the “Acquisition Reform” policy of the Department of Defense (DoD) and its constituent government agencies. The intent of Acquisition Reform was to change the way government agencies defined the requirements for systems and materiel, and the associated engineering data (Technical Data Packages (TDPs)) to be procured by the government. In short, the overseeing government authority dictated that government agencies should “avoid government-unique

requirements and rely more on the commercial marketplace.” The intent was to move the definition of requirements to commercial and non-government sources where possible.

With regards to engineering drawing practices, the most significant impact of this reform was a new preference for the use of non-military specifications and standards in cases where they adequately met the needs of the project. That is, military specifications (MIL-SPECS) and military standards (MIL-STDS) were no longer the preferred standardization tools for defining engineering drawing requirements on government projects. Government agencies had to obtain a waiver to use certain MIL-SPECS and MIL-STDS on their procurement documents. Likewise, contractors also were restricted in their ability to use and reference certain MIL-SPECS and MIL-STDS without obtaining a waiver. If government-specific requirements were critical, a preference to use performance-based specifications (MIL-PRF) rather than MIL-SPECS and MIL-STDS was also stated.

The idea to use non-government specifications and standards was sound: it alleviated the government of the burden and associated expense of developing and maintaining specifications and standards which in many cases were almost identical in scope to non-government standards; it eliminated the sometimes overly restrictive requirements imposed by MIL-SPECS and MIL-STDS, thereby reducing the cost to the government and ultimately the taxpayer; it required procuring agencies to very carefully consider how restrictive and costly the requirements they imposed in their contracts and purchase orders were; lastly, it made no sense to duplicate non-government specifications and standards merely to fit in with the government procurement model – upon closer inspection there was no real need to reinvent every wheel, so-to-speak. Indeed, my first foray into the world of national standards development was as a member of the Drawing Practices Group (DRPRG) which was tasked with converting MIL-STD-100 into a non-government standard, which eventually led to the creation of ASME Y14.100, which is the foundation upon which the later revisions of the DRM is built.

2005 – A Change is in the Air: The Waiver Requirement is Waived.

In 2005 the Department of Defense reversed the waiver requirement to use MIL-SPECS and MIL-STDS on procurement documents – this change in stance can be found in DoD Policy Memo 05-3, the content of which is included below. The change was in response to the difficulty, extra work, and extra expense that government agencies had experienced when there was a real need for a MIL-SPEC or MIL-STD that fell under waiver requirements. People and agencies procuring systems for the government “got the message” about carefully considering the cost implications of every specification and standard referenced in a procurement document. According to sources in the defense community, the culture had changed, and Acquisition Reform had its desired effect. The time had come to move on. As stated in the memo, this was not a call to return to “the old way of doing business.” The DoD had evolved, the beneficial changes brought about by Acquisition Reform had become part of the DoD culture, and it was time to lift a potentially unnecessary restriction. Of course, time will tell how this all plays out.

The material in Section 2 and the rest of the DRM has been revised to reflect the removal of the waiver requirement.

Excerpt from DoD Policy Memo 05-3:

“MEMORANDUM FOR THE STANDARDIZATION EXECUTIVES OF THE MILITARY DEPARTMENTS AND DEFENSE AGENCIES

SUBJECT: Policy Memo 05-3, ‘Elimination of Waivers to Cite Military Specifications and Standards in Solicitations and Contracts’

On October 14, 2004, the Under Secretary of Defense for Acquisition, Technology and Logistics signed the Defense Acquisition Guidance. Paragraph 11.6 of this Guidance states that "it is no longer required to obtain a waiver from the Milestone Decision Authority to cite military specifications and standards in solicitations and contracts."

We are in the process of preparing a formal change to DoD 4120.24-M, "Defense Standardization Program Policies and Procedures," to eliminate the waiver requirement from this document to be consistent with the Under Secretary's direction. Until such a formal change can be issued by the DoD Directives Office, this policy memorandum deletes Section C3.8 and all of its paragraphs and subparagraphs regarding waivers from DoD 4120.24-M.

I request that you take appropriate action to ensure that everyone in your acquisition and logistics communities is aware that a waiver to cite military specifications and standards in solicitations and contracts is no longer required. As noted in the Defense Acquisition Guidance, however, this waiver elimination should not be interpreted as returning to the "old way of doing business," but as recognition of the cultural change that took place in DoD regarding the proper application of specifications and standards. We need to ensure that those in the acquisition and logistics communities have the flexibility to assess program requirements, make good decisions, and where appropriate, require conformance to military specifications and standards.”

Note:

As of April 2008 DoD 4120.24-M is still active; the revisions described above are in process. However, as stated above, the Policy Memo deletes the section in DoD 4120.24-M that mandates waivers for invoking MIL-SPECS and MIL-STDS.

The Preface detailing the history and effects of Acquisition Reform from Section 2 in the 10th Edition of the DRM has been moved to new Non-Mandatory Appendix C at the end of Section 2.

PREFACE 2 CHANGES IN MIL-DTL-31000C AND THEIR EFFECT ON TDPS

General Description of Changes in MIL-DTL-31000C:

- In July 2004 MIL-DTL-31000 was revised from revision B to revision C. In general, revision C of MIL-DTL-31000 includes material addressing four new topics:

- New content supporting the use of 3D data as part or all of a Technical Data Package (TDP) has been added.

- New content on special packaging instructions drawings/models has been added.

- New content on the use of digital approval systems has been added.

- New content in Appendix A instructs procurement officials to require software documentation in the TDP for each software product in a statement of work has been added.

Several other changes related to cancelled military standards and other government documents.

- All references to the Dept. of Defense Index of Specifications and Standards (DODISS) have been removed and replaced by references to the Acquisition Streamlining and Standardization Information System (ASSIST) database.

- Reference to the following MIL standards has been removed:

-

- MIL-STD-974

- MIL-E-5007

- MIL-E-8593

- MIL-M-38761/1

- MIL- HDBK-248

The major change to MIL-DTL-31000 was the addition of new material addressing three-dimensional (3D) digital data used as all or part of a TDP. With this recognition of the expanding role of 3D data, two new types of TDPs were required to differentiate between TDPs based on 2D and 3D data (Type 2D and Type 3D).

The coverage of 3D data in MIL-DTL-31000C parallels the shift in industry toward greater use of 3D data throughout the design-manufacturing-operation-decommissioning lifecycle of a product and thus is consistent with general trends in industry. Accordingly, an attempt to standardize the use of 3D data in industry has been addressed by the standard ASME Y14.41-2003 Digital Product Definition Data Practices. Careful review of the changes related to 3D data in MIL-DTL-31000 reveals an alignment between MIL-DTL-31000C and ASME Y14.41-2003. In keeping with this trend, a new chapter (SECTION 26) has been added to this DRM, addressing the use of 3D digital data as a design deliverable and as part of a TDP. Thus, a major emphasis of this revision of the DRM has been to address the use of 3D data as part of the design process.

MIL-DTL-31000C includes several additional requirements for using of 2D and 3D data that are not found in ASME Y14.41-2003. The following are quotes from MIL-DTL-31000C:

- In general, solid models shall be in accordance with (ISO) 10303 Standard for the Exchange of Product model data (STEP), or in a native 3D CAD format capable of being exported to ISO 10303 STEP format.”

Note: ISO 10303 is not referenced in ASME Y14.41-2003, and adherence to the STEP format defined in ISO 10303 is not required by ASME Y14.41-2003. - “When 3D TDP data is used, the solid models shall display classification marking clearly visible when the solid model is first opened.”

Note: ASME Y14.41-2003 states that “the security marking shall be constantly displayed for all mediums of views” which is slightly different than requiring the classification markings to be visible when the solid model is first opened. However, the requirements in ASME Y14.41-2003 seem to include the requirement above. - “A 3D TDP shall be of detail and content sufficient for the support of production, engineering and logistics support, and be based on fully parametric, computer based solid model and capable of generating, when specified, 2D engineering drawings.”

Note: ASME Y14.41-2003 does not explicitly require models to be fully parametric. - “Both Type 2D and Type 3D TDPs shall open in the appropriate software without regeneration errors or warnings.”

Note: ASME Y14.41-2003 does not include this requirement. - “Data on 2D drawings based on the 3D solid models shall be sourced to the maximum extent possible from the 3D solid model. There shall be no conflict in data between the 3D solid model and its associated 2D drawing.”

Note: ASME Y14.41-2003 does not explicitly state that 2D drawings should be sourced to the maximum extent possible from the 3D solid model. However, ASME Y14.41-2003 does lead the reader to this conclusion.

MIL-DTL-31000B stated that TDPs based on digital data are preferred. MIL-DTL-31000C expands this preference by stating “3D based TDPs are generally preferred especially when the item is mostly mechanical in nature, is subject to a significant number of interfaces with other systems, or in which future design upgrades and changes are likely.” Thus the recognition of the importance of 3D data and even a preference for its use has been stated in the document.

Several of the TDP Option Selection Worksheets in MIL-DTL-31000C have been modified and new worksheets have been added to address the use of models in a TDP.

The following material lists the major changes in MIL-DTL-31000 on a clause-by-clause basis.

2.1 SCOPE

2.1.1 Purpose. This section establishes the essential requirements for the preparation and revisions of engineering drawings, requirements for drawing disclosure, hard copy drafting requirements, digital data files (2D and 3D) and associated lists prepared under the requirements of ASME Y14.100-2004. It is essential that ASME Y14.100 be used in close conjunction with ASME Y14.24, ASME Y14.34M and ASME Y14.35M for establishing the basic requirements for commercial applications. Department of Defense (DoD) needs and requirements often extend beyond commercial applications. To invoke these additional DoD requirements, drawings must be part of a Technical Data Package (TDP) per MIL-DTL-31000. Under the requirements of MIL-DTL-31000, drawings, models, and related documentation are required to adhere to default and selected specifications and standards. TDPs may be classified as Type 2D or Type 3D, and are composed of one or more TDP elements and related TDP Data Management Products. These requirements support all Departments and Agencies of the Department of Defense’s Defense's policy of acquiring only those engineering drawings and associated lists that are needed.

Note: "Drawing Categories" and "Forms", formerly defined in MIL-D-1000 and drawing "LEVELS" formerly defined in DOD-D-1000B no longer apply.

2.1.1.1 Language. Unless otherwise specified in the contract or by an international agreement, drawings and associated documents shall be in the English language.

2.1.1.2 Selective Application. Selection of the TDP elements and the TDP data management products to make up a TDP must be based on the Government’s needs for technical data required to support the acquisition and life cycle support strategies for the product being documented. The Government’s need for technical data varies greatly from program to program. It may range from conceptual design data for concept evaluation to a complete set of detailed design data for procurement of items essentially identical to the original item.

2.1.1.3 Tailoring Implementation. All contractual requirements, government or non-government herein are subject to tailoring. These requirements, as well as the requirements of specific TDP elements and TDP data management products selected for inclusion in the TDP, should be tailored by the Government prior to release of the solicitation. This includes the requirements stated in data item descriptions, Government or non-Government standards and requirements for the media and methods of delivery. Furthermore, a contractor may recommend additional tailoring of TDP requirements as specified in a solicitation or contract using the guideline of MIL-HDBK-248

2.1.2 Classification. This SECTION 2 covers the following TDP elements and TDP data management products.

2.1.2.1 TDP elements for Drawings. (See PARAGRAPH 2.5) When MIL-DTL-31000 is applied to the contract or Purchase Order (PO) in order to obtain data, the referenced Data Item Descriptions (DIDs) must be listed as applicable on the Contract Data Requirements List (CDRL) (DD Form 1423). See APPENDIX A FIGURE 2A-9. This requirement is exempt when DOD FAR Supplement 27.475-1 is cited.

- Conceptual design drawings. (Ref: DI-SESS-81001C)

- Developmental design drawings and associated lists. (Ref: DI-SESS-81002D)

- Product drawings and associated lists. (Ref: DI-SESS-81000C)

- Commercial drawings and associated lists. (Ref: DI-SESS-81003C)

- Special inspection equipment (SIE) drawings and associated lists. (Ref: DI-SESS-81004C)

- Special tooling (ST) drawings and associated lists. (Ref: DI-SESS-81008C)

- Specifications (Ref: MIL-STD-961 and IEEE 12207.0, 12207.1, and 12207.2)

- Packaging (Ref: MIL-STD-2073-1)

2.1.2.2 TDP data management products. (See PARAGRAPH 2.5.5)

- Source control drawing approval request. (Ref: DI-SESS-81010C)

- Drawing number assignment. (Ref: DI-SESS-81011C)

- Proposed critical manufacturing process description. (Ref: DI-SESS-81012C)

2.1.3 Reference to the Application of Non-Government Standards (NGSs). ASME Y14.100-2004 is the mandatory requirements document for engineering drawing practices. This move from MIL-STD-100 to ASME Y14.100 was part of Acquisition Reform Movement described in Non-Mandatory Appendix C at the end of SECTION 2 of the DRM. With the elimination of the waiver requirement for using MIL-SPECS and MIL-STDS discussed in Preface 1, MIL-SPECS and MIL-STDS may be used if a NGS is not available or fails to support basic document preparation requirements. The user may also detail the needed engineering drawing practice directly in the Statement of Work (SOW), Contract or Purchase Order (PO) if desired. Historically, canceled MIL-STD-100G and related applicable specifications were used to provide military requirements in excess of commercial applications. When MIL-STD-100G was canceled, those applicable military specifications and standards were moved to Appendices B thru E of ASME Y14.100-2004. To invoke these Appendices in a Statement of Work (SOW), contract or purchase order requires “tailoring” as described in Appendix “A” of ASME Y14.100-2004. The use of MIL-STD-100G will continue on current and on-going contracts. Switching from MIL-STD-100 to ASME Y14.100 will not be required unless economically feasible or otherwise justified.

2.1.4 Reference to the Application of the Appendices A thru E of ASME Y14.100. MIL-STD-100 has largely been replaced by Non-Government Standards (NGS) ASME Y14.100 including Appendices A thru E. Reasons for invoking the appendices in entirety, or in part, are listed as follows:

- Contains only Government unique requirements and is restricted for use to those DoD activities.

- Have DoD peculiar logistics requirements.

- Have specific & fully justifiable requirement for TDP delivery & maintenance control by a DoD design activity.

- Essential that drawings indicate a government design activity CAGE Code.

2.1.4.1 Rule Regarding the Use of the Appendices B thru E of ASME Y14.100. ASME Y14.100 addresses engineering drawing practices in commercial applications or where DoD design requirements need not be under the change control authority of a DoD activity. All referenced documents and detail associated with basic drawing practices are contained in ASME Y14.100. Accordingly, the Appendices B thru E of ASME Y14.100 and appropriate revision as applicable, must always be used in conjunction with ASME Y14.100. In addition, since requirements for broad areas, of subject material are now addressed by individual ASME standards, ASME Y14.100 must be used in conjunction with:

ASME Y14.24 Types and Application of Engineering Drawings

ASME Y14.34M Associated Lists

ASME Y14.35M Revision to Drawings and Associated Lists

2.1.5 Tailoring Guidance for Checking Compliance With Contractual Requirements. To ensure proper application of ASME Y14.100 any tailoring provided by Appendix “A” including the Appendices B thru E must also be consistent with MIL-DTL-31000, TDP Option Selection Worksheets. Tailoring must exclude unnecessary requirements for invitations for bids, request for proposals and Contract Data Requirements Lists (CDRLs). See APPENDIX A FIGURE 2A-9. It is essential that the numerous referenced documents be reviewed to exclude unnecessary requirements in accordance with the program or end item requirements by tailoring. The following procedures must be reviewed to determine if a requirement is not a current operational procedure, and an alternate procedure would be more economical in complying with the contract in the acquisition of documents. (See TAILORING that follows.)

TAILORING

(As presented in Appendix “A” of ASME Y14.100-2004)

A. Drawing Media (Choose all that apply)

- Non-digital (Specify___________________)

- Digital Data (Specify__________________)

- Other (Specify_______________________)

B. Drawing Format (Choose one)

- Contractor

- Government (forms supplied by the Government)

- Government (forms supplied by the contractor)

C. Drawing Sheet Size (and Format) (Choose one)

- ASME Y14.1

- ASME Y14.1M

D. Application Data (Choose all that apply)

- Contractor’s option

- Required

- On drawing

- By reference. (Specify______________________)

- Contractor option

- General use or multi-use notations

- allowed

- not allowed

E. Drawing Detail (ASME Y14.24) (Choose all that apply)

- Monodetail

- Multidetail

- Tabulated

F. Dimensioning and Tolerancing (Choose all that apply)

- Metric

- Decimal-inch

- Application of ASME Y14.5M

- Specific issue (revision) required (Specify issue____________________)

- Issue in effect (Specify issue____________________)

G. Drawing Notes (Choose One)

- On drawing

- By reference (Specify_____________________)

- Contractors option

H. Types of Drawings (ASME Y14.24) (Choose one)

- Contractor selects

- Government selects

I. Maintenance of Multi-Sheet Drawings (ASME Y14.35M) (Choose all that apply)

- Drawing revision level (DoD preferred)

- All Sheets same revision level

- Sheet revision level

J. Redrawn Drawings (redrawing without change) (ASME Y14.35M) (Choose one)

- Advance revision level

- Revision level is not advanced

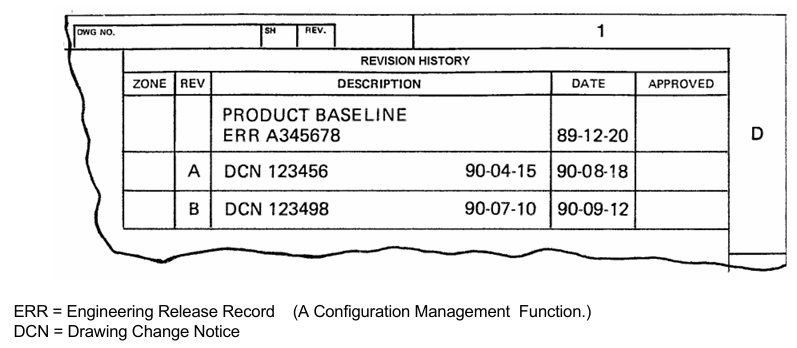

K. Maintenance of Revision History (Choose all that apply)

- Contractor’s option

- Optional methods

- Remove one or more revision record as required

- Remove all previous revision history

- Remove all revision history but retain line entry for revision authorization and date of revision

- Remove all except revision preceding current

- Maintain revision history in its entirety

L. Adding Sheets (ASME Y14.35M) (Choose all that apply)

- Contractor’s option

- Optional methods

- Renumber sheets using consecutive whole numbers

- Number added sheets in decimal-number sequence

- Number added sheets in alpha-numeric sequence

M. Deleting Sheets (ASME Y14,35M) (Choose all that apply)

- Contractor’s option

- Optional methods

- Renumber all affected remaining sheets

- Affected remaining sheets not renumbered (revision status of sheets block is updated with notations such as CANC or DEL)

N. Markings on Engineering Drawings (Choose one)

- Special items and processes apply

- Applicable symbols (Specify___________________________)

- Applicable special notes (Specify_______________________)

- Special items and processes do not apply

O. Associated Lists (ASME Y14.34M) (Choose all that apply)

- Non-digital (Specify_______________________)

- Digital Data (Specify______________________)

- Other (Specify__________________________)

P. Types of Associated Lists (ASME Y14.34M) (Choose all that apply)

- Parts Lists

- Integral

- Separate

- Contractor’s option

- Application List

- Data Lists

- Index Lists

- Indentured Data List

- Wire List

- Other (Specify________________________)

Q. Angle of Projection (ASME Y14.3M) (Choose one)

- 3rd Angle

- 1st Angle

R. Language (Choose one)

- English required

- Other (Specify_________________)

S. Applicability of Appendices

- Appendix B

- as detailed herein

- as modified_________________

- Appendix C

- as detailed herein

- as modified_________________

- Appendix D

- as detailed herein

- as modified_________________

- Appendix E

- as detailed herein

- as modified_________________

2.1.6 General Guidance for Checking the Completeness of Drawing Requirements of a Technical Data Package (TDP). (MIL-HDBK-288) The following topics should be reviewed on all developmental and product engineering drawings. (Formerly Level 2 AND 3 of DOD-D-1000) NOTE: MIL-DTL-31000 SUPERSEDES DOD-D-1000.

| TOPIC | CONTROLLING DOCUMENT | DRM SECT | |

| a. | Drawing size and format | ASME Y14.1 & Y14.1M | 6 |

| b. | Drawing title (nomenclature) | ASME Y14.100 including Appendix C, H6 Federal Item Name Directory (FIND) | 6 |

| c. | Drawing number | ASME Y14.100 including Appendix D | 7 |

| d. | Authorized signatures | ASME Y14.100 | 2 |

| e. | Scale | ASME Y14.100 | 3 |

| f. | Contract number in title block | MIL-DTL-31000 | 6 |

| g. | Applications blocks | ASME Y14.1 & Y14.1M | 6 |

| h. | Sheet numbering | ASME Y14.1 & Y14.1M | 6 |

| i. | Zoning | ASME Y14.1 & Y14.1M | 6 |

| j. | Security classification | DoD 5220.22-M | 6 |

| k. | Lettering/Spelling | ASME Y14.2M | 3 |

| l. | Legibility | MIL-PRF-5480 | 3 |

| m. | Dimensions and tolerances | ASME Y14.5M-1994 | 5 |

| n. | Graphic symbols | ASME Y14.100 including Appendix B | 3 |

| o. | Abbreviations | ASME Y14.38M | 24 |

| p. | Items covered by Government or industry standards | ASME Y14.100 including Appendices B thru E | 10 |

| q. | Identification of rights in data (limited rights legends) | DFARS 252.227 | 6 |

| r. | Reference dimensions | ANSI Y14.5M-1994 | 5 |

| s. | Existing drawings, use and submission | MIL-DTL-31000 | 2 |

| t. | Part numbers | ASME Y14.100 including Appendix D | 7 |

| u. | Part marking | ASME Y14.100 including Appendix B, MIL-STD-130 & MIL-T-13231 | 7, 11 |

| v. | Parts List | ASME Y14.34M | 10 |

| w. | Company standard documents | MIL-DTL-31000 | 1 |

| x. | Reference documents | MIL-DTL-31000 | 7 |

| y. | Standard supply system items used wherever possible | MIL-DTL-31000 | 2 |

| z. | Revision block | ASME Y14.35M | 6 |

| aa. | Distribution statement marking | DoD D 5230.24 | 6 |

NOTES:

- Appendices B thru E of ASME Y14.100-2004 occur as the result of MIL-STD-100G being canceled.

2.1.7 Check List of Detail Requirements for Engineering Drawings. Appendix B of this section may be used as a check list in preparing engineering drawings for Technical Data Package (TDP) elements for developmental and production phases of system acquisitions.

2.1.8 Specifications, Standards and Handbooks. The following Government and Non-Government applicable specifications, standards and handbooks form a part of this Drawing Requirements Manual (DRM) to the extent specified herein. Unless otherwise specified, the issues of these documents are those listed in the issue of the Acquisition Streamlining and Standardization Information System (ASSIST Database) and supplement thereto, cited in the solicitation. The status of the documents listed below was current when this DRM was published in 2008 together with ASSIST DATABASE as augmented by the ASSIST Update.

2.2 APPLICABLE DOCUMENTS. Note: DoD Policy Memo 05-3 “Elimination of Waivers to Cite Military Specifications and Standards in Solicitation and Contracts” has eliminated the need for waivers to use MIL-SPECS and MIL-STDS on DoD contracts. (See PREFACE 1, Section 2)

| DOC NO. | DOCUMENT TITLE |

| FED-STD-376B | Preferred Metric Units for Use by the Federal Government |

| DOD-D-1000 | Drawing, Engineering & Associated Lists (Inactive For New Design) (Use MIL-DTL-31000C) |

| MIL-PRF-5480G | Data, Engineering Technical Reproduction, Requirements for |

| MIL-DTL-31000C | Detail Specification Technical Data Packages (Supersedes: DOD-D-1000, MIL-T-47500 and MIL-T-31000B) |

| MIL-M-38761B | Microfilming and Photographing Engineering/Technical Data and Related Documents, Requirements for (Inactive For New Design after 6-1-95) (Use JEDMICS) |

| MIL-T-47500 | Technical Data Package, General Specification for (Inactive For New Design) Use: MIL-DTL- 31000C) |

2.3 Definitions

2.3.1 Associated Lists. An associated list is a tabulation of engineering information on a drawing or set of drawings pertinent to an item depicted in a Technical Data Package (TDP). (Ref: ASME Y14.34M)

2.3.2 Commercial and Government Entity (CAGE) Code. A five-character code listed in Cataloging Handbook H4/H8, Commercial and Government Entity (CAGE) Code, which is assigned to commercial and Government activities that manufacture or develop items or provide services or supplies for the Government. When used with a drawing number or part number, the CAGE Code designates the design activity from whose series the drawing or part number is assigned, The CAGE Code was previous called manufacturer’s code, code identification number or Federal Supply Code for Manufacturers (FSCM).

2.3.3 Commercial Drawings. Drawings prepared by a commercial design activity following its drawing format and standards for the development and manufacture of the product without government expense.

2.3.4 Commercial Inspection Equipment (CIE). Standard equipment of commercial design that has not been modified and has universal application without limitations to a specific commodity, item, or component which is advertised or cataloged as being available to the trade or to the public on an unrestricted basis and is used to determine compliance to Technical Data Package (TDP) requirements.

2.3.5 Commercial Item Description (CID). A simplified product description or specification that describes by salient functional or performance characteristics the available and acceptable commercial products that will satisfy the Government's needs. CIDs are prepared under guidelines issued by the General Services Administration’s Federal Supply Service (GSA-FSS) and are listed in the ASSIST DATABASE.

2.3.6 Commercial Product. A product, material, component, subsystem or system sold or traded to the general public in the course of normal business operations at prices based on established catalog or market prices.

2.3.7 Company Standard. A company standard is a document that establishes uniform and preferred practices and techniques, and sets limitations for engineering and technical applications for items, materials, processes, methods, design and engineering practices unique to that company. (NOTE: Company standards are not considered to be non-Government standards.)

2.3.8 Competent Manufacturer. A manufacturer that has demonstrated the capability to produce similar products at the same state of the art in the same or similar lines of technology.

2.3.9 Conceptual Design Drawings. Drawings used to verify preliminary design and engineering. They are one of the factors used to determine that the technology is feasible and that the design concept has utility against stated military requirements in order to reduce technical uncertainty. These drawings may evolve into developmental design drawings.

2.3.10 Critical Manufacturing Process. A process is critical if it is the only known method which will result in the production of an acceptable item.

2.3.11 Design Maturity. The extent to which the final design or configuration of an item has been defined by the engineering process. For example, the design of a sheet metal cover having holes in its mounting hole pattern fully dimensioned and tolerance for final size, location and orientation would be considered to be more mature than the design of a similar cover having its mounting hole pattern defined as “Drill at Assembly”.

2.3.12 Detail Design Data. Technical data that describes the physical configuration and performance characteristics of an item or component in sufficient detail to ensure that an item or component produced in accordance with the technical data will be essentially identical to the original item or component. (DFARS, Part 227).

2.3.13 Detail Specification. A specification that specifies design requirements, such as material to be used, how a requirement is to be achieved, or how an item is to be fabricated or constructed. A specification that contains both performance and detailed requirements is still considered a detail specification. (Ref: MIL-STD-961)

2.3.14 Design Disclosure Information. The complete description, including all specifications, standards, drawings, lists and critical processes necessary to manufacture an item without recourse to additional design or engineering services.

2.3.15 Design Drawings. Drawings of a conceptual or developmental nature prepared for use in evaluating proposed technology, design concept, design approach, and fabrication of hardware for test or experimentation in response to stated requirements. Although ideally design drawings would evolve to product drawings, the requirements of ASME Y14.100 may not be applicable.

2.3.16 Developmental Design Drawings. Drawings used to fabricate developmental hardware for test or experimentation of a prototype or experimental material and define a specific design approach. In addition, the data shall be suitable for evaluation of the inherent ability of the design to attain the required performance. These drawings may evolve into product drawings.

2.3.17 Drawing Form. A sheet of drafting material displaying the basic format features such as title block, general tolerance blocks and margins in accordance with ASME Y14.1 or ASME Y14.1M.

2.3.18 Drawing Format. The arrangement and organization of information within a drawing, including the size and arrangement of blocks, notes, lists, revisions, the use of optional or supplemental blocks, etc.

2.3.19 End Product. An end product is an item, such as an individual part or assembly, in its final or completed state. (ASME Y14.24). Also known as an end item.

2.3.20 Inspection Equipment. Equipment such as dimensional gauges, measurement equipment, test fixtures, electronic and physical test equipment, and other test equipment that is used for examination, evaluation and test of a product to determine its conformance to drawings, specifications, or other requirement documents.

2.3.21 Item (Item of Supply). An end item, component, or part, records for which are maintained for stock, storage, and issuance in support of military requirements. (Examples of items of supply are airplanes, ships, trucks, radar, radar components, hand tools, fasteners, uniforms, and food.)

2.3.22 Non-Government Standard (NGS). A Standardization document developed by a private sector association, organization, or technical society which plans, develops, establishes, or coordinates standards, specifications, handbooks, or related documents. Company standards are not considered as non-Government standardization documents.

2.3.23 Performance Specification. A specification that states requirements in terms of desired results with criteria for verifying compliance, but without stating the methods for achieving the required results. A performance specification defines the functional requirements for the item, the environment in which it must operate and interface and interchangeability characteristics. (Ref: MIL-STD-961)

2.3.24 Physical Configuration Audit (PCA). The formal examination of the “as built” configuration of an item against its technical documentation to establish or verify the configuration item’s product baseline.

2.3.25 Product Drawings. Engineering drawings which provide the design, engineering, manufacturing and quality support information necessary to permit a competent manufacturer to produce an interchangeable item which duplicates the physical and performance characteristics of the original design without additional design engineering or recourse to the design activity.

2.3.26 Reference Documents. Documents that contain required engineering data that is too voluminous to be placed upon the drawing or are applicable to more than one item, process, or material.

2.3.27 Shipping List. A shipping list is a tabulation of all documents included in a delivery or shipment.

2.3.28 Special Test Equipment (STE) (also called Special Inspection Equipment (SIE)). Either single or multipurpose integrated test units engineered, designed, fabricated, or modified to accomplish special purpose testing in performing a contract. It consists of items or assemblies of equipment that are interconnected and interdependent so as to become a new functional entity for testing purposes (FAR 45.101).

2.3.29 Special Tooling. Unique tooling which is mandatory to the manufacture of an acceptable item. It differs from tooling designed to increase manufacturing efficiency in that the use of the special tool imparts some characteristic to the item which is necessary for satisfactory performance and cannot be duplicated through other generally available manufacturing methods. Examples of special tooling would be jigs, dies, fixtures, molds, patterns and other equipment or manufacturing aids that absolutely must be used to produce a satisfactory item.

2.3.30 Specifications. A specification is a document prepared specifically to support acquisition which clearly and accurately describes the essential technical requirements for purchasing material. Procedures necessary to determine that the requirements for purchased items, materials, and processes covered by the specifications have been met shall also be included. (The term “specification” is also used to describe the requirements specified on a drawing or other contractually binding document, such as the material, dimensions and tolerances, surface texture, finish, heat treatment, physical, and other requirements.)

2.3.31 Standard Microcircuit Drawing. A Government unique drawing type used to define the physical and performance characteristics of commercial microcircuits in Federal Supply Class 5962 used in military applications.

2.3.32 Standardization Directory (SD-1). A document issued quarterly that identifies standardization responsibility assignments by Federal Supply Classes and Standardization Areas and provides the addresses of the military offices, federal civil agencies, and non-Government standards bodies participating in the Defense Standardization and Specification Program (DSSP).

2.3.33 Standardization Document. A document, such as a specification, standard or handbook developed for the purpose of standardizing item, materials, processes or procedures.

2.3.34 Standards and Specifications. As used herein, includes all non-Government standards, Federal and Military Standards and Specifications, Commercial Item Descriptions (CIDs), Standardized Military Drawings (SMDs) and Purchase Descriptions (PDs) which describe the essential technical requirements for purchased items materials and processes.

2.3.35 Tailoring of the Specification. A process of consideration by the procuring activity to determine the selection of data for the appropriate level and types with possible downward tailoring of engineering drawings and associated lists in order to minimize the government’s need for drawings to support the following:

- Exploratory Development (bread board)

- Advanced Development (brass board)

- Engineering Development (service test)

- Production (prototype)

- Production

2.3.36 Technical Data. Recorded information, regardless of the form or method of recording, of a scientific or technical nature (including computer software documentation). The term does not include computer software or data incidental to contract administration, such as financial or management information. (DFARS Part 227).

2.3.37 Technical Data Package (TDP). The technical description of an item adequate for supporting an acquisition strategy, production, engineering, and logistic support. The description defines the required design configuration and procedures to assure adequacy of item performance. It consists of all applicable technical data such as drawings, models, associated lists, specifications, standards, performance requirements, quality assurance provisions, and packaging details.

2.3.38 Technical Data Package Document. A document that is part of a TDP element or TDP data management product.

2.3.39 Technical Data Package (TDP) Element. A TDP element is a data product that is an actual component of the TDP. A TDP element provides all or part of the design disclosure information necessary to define the item being documented by the TDP.

2.3.40 Technical Data Package (TDP) Data Management Product. A data product used to monitor and control the development and maintenance of the TDP. A TDP data management product contains information about the TDP rather than the item being documented.

2.3.41 TDP Drawing/Model Elements. The provision of necessary design disclosure information to the degree required for the drawing/model element selected listed as follows:

2.3.41.1 TDP Element, Conceptual Design Drawings/Models. (per DI-SESS-81001C) Drawings/models that disclose engineering design information sufficient to enable the evaluation of an engineering concept as meeting stated requirements. Formerly LEVEL 1 of DOD-D-1000 (models were not addressed in DOD-D-1000).

2.3.41.2 TDP Element, Developmental Design Drawings/Models & Limited Production Design. (per DISESS-81002D) Drawings/models that disclose sufficient design information to support the manufacture of a production prototype or a limited production model. Formerly LEVEL 2 of DOD-D-1000 (models were not addressed in DOD-D-1000).

2.3.41.3 TDP Element, Product Drawings/Models. (per DI-SESS-81000C) Drawings/models that disclose sufficient engineering definitions to enable any competent manufacturer to produce a quantity of items which are interchangeable with the original design without the need for:

- Additional product design effort.

- Additional design data.

- Recourse to the design activity.

(Formerly LEVEL 3 of DOD-D-1000 (models were not addressed in DOD-D-1000).

2.3.41.4 TDP Element, Commercial Drawings/Models. (per DI-SESS-81003C) Drawings/models that disclose information in support of end items that are commercially developed items, off-the-shelf items or items not developed at government expense.

2.3.41.5 TDP Element, Special Inspection Equipment (SIE) Drawings/Models. (per DI-SESS-81004C) Drawings/models prepared to provide the data required to permit the limited production of SIE which duplicates the physical and performance characteristics of the original SIE. SIE is also known as Special Test Equipment (STE).

2.3.41.6 TDP Element, Special Tooling Drawings/Models. (per DI-SESS-81008C) Drawings/models prepared to provide the data necessary to enable a competent manufacturer to produce an item which duplicates the physical and performance characteristics identical to those of the original tooling.

2.3.41.7 TDP Element, Specifications. (Per appropriate DID listed in MIL-STD-961) Specifications prepared as coordinated, limited coordination or “USED IN LIEU OF” limited coordination military specifications in accordance with MIL-STD-961.

2.3.41.8 TDP Element, Packaging. (Per appropriate DID listed in MIL-STD-2073-1.) Packaging requires the generation of a TDP containing packaging data in the Statement Of Work (SOW). See 2.3.41.9.

23.41.9 TDP Element, Special Packaging Instructions Drawings/Models. (New in MIL-DTL-31000C) Drawings/models prepared to provide the data required to manufacture special packaging which is mandatory to successfully produce and transport the item.

2.3.42 Verification. All examination tests and inspections necessary to verify that an item meets the physical and functional requirements for which it was designed, to verify that a component, part or subassembly will perform satisfactorily in its intended application, or that an item conforms to specified requirements.

2.4 Drawing and Model Requirements

2.4.1 Drawings and Models Prepared to Data Item Description (DID) Requirements. Engineering drawings and models are prepared to meet the requirements of specifications and standards referenced on Data Item Descriptions (DIDs) as required by the contract or purchase order as cited by Statement of Work (SOW). These drawings and models are normally specified on the Contract Data Requirements List (CDRL) (FORM DD 1423) (See APPENDIX A FIGURE 2A-9) along with the Technical Data Package (TDP) elements for drawings required to provide the necessary design disclosure. Combination of TDP elements may be specified in the contract or purchase order.

2.4.1.1 If TDP Elements Are Not Specified. On a contract where the Technical Data Package (TDP) elements for drawings and models are not specified, or on design activity R&D and commercial work, use the following guide:

- Prepare all work on the design activity standard engineering drawing format.

- Use the design activity’s drawing and part numbering system.

- Company, government and industry association standards or specifications may be omitted for parts, processes and materials, but their use is encouraged when economically feasible.

- Use of standard parts is recommended.

- Freehand sketching is permissible, and drawings need not be to an exact scale.

- Drawings must be legible and reproducible.

- Use of drafting standards for symbols and conventions is recommended.

- Use of simplified drafting techniques is encouraged.

- Drawings must contain sufficient information necessary for fabrication, installation, assembly, procurement and inspection.

- 3D solid models and drawings based on 3D solid models should conform to SECTION 26 and paragraph 26.34 and sub-paragraphs in particular.

2.4.1.2 When TDP Elements Are Specified. If a contract specifies Technical Data Package (TDP) elements for engineering drawings, models, or associated lists, these elements shall be prepared to the disclosure level designated. When preparing an engineering drawing, model, or associated list, the contract or purchase order should list the following requirements of TDP element as listed:

- Conceptual Design Drawings/Models and Associated Lists per paragraph 2.3.41.1.

- Developmental Design Drawings/Models and Associated Lists per paragraph 2.3.41.2.

- Product Drawings/Models and Associated Lists per paragraph 2.3.41.3.

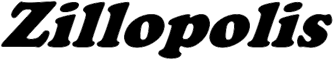

Use the following guide for TABLE 2-1.

- Whether a Government Design Activity or Contractor Design Activity designation and identity as assigned by Commercial And Government Entity (CAGE) 5-digit code is to be placed in the Title Block of the engineering drawing or associated list.

- Whether a Government Design Activity or Contractor Design Activity drawing numbers will be assigned.

- If Government Design Activity drawing numbers are to be assigned, identify the assigning activity. If Government drawing formats are to be supplied, identify the source.

- Whether the mono-detail or multi-detail drawing system will be used.

- Which kinds of associated lists are required.

- Assembly level at which associated lists will be prepared.

- Whether associated lists shall be integral with, or separate from, the engineering drawing.

- Which drawing format, type, class and quality of stock are required.

Table 2-1

2.4.1.3 Existing Engineering Drawings/Models and Associated Lists. Engineering drawings, models and associated lists prepared prior to the above requirement of PARAGRAPH 2.4.1.2 are acceptable if the engineering drawings, models and associated lists have been previously accepted by the Government, or if they meet the following requirements:

- They are acceptable for entry into the government's repository system. (i.e. are identified by name and address of design activity, Commercial and Government Entity (CAGE) code, drawing nomenclature, drawing (part) number, in accordance with MIL-STD-100, and contract number).

- The format, legibility requirements, drawing practices, modeling practices, and symbols used (including the use of legends/explanations for nonstandard symbols) are such that their intent and interpretation of all requirements are clear and unambiguous.

- They provide the necessary design disclosure information for the drawing or model TDP element for which they are furnished.

2.5 TECHNICAL DATA PACKAGE (TDP) DRAWING/MODEL ELEMENTS.

2.5.1 TDP Elements. TDPs shall consist of one or more of the following TDP elements as specified on the contract or purchase order.

2.5.1.1 TPD DI-SESS-81001C Conceptual Design Drawings and Models. These drawings and models shall be legible and appropriate for the mode of presentation. Sketches, layout drawings and combinations of types of engineering drawings may be used to convey the engineering concept in such a manner that the engineering information is understandable to cognizant engineers and scientists. Unless otherwise specified, the requirements of ASME Y14.100 including Appendices A thru E do not apply. (Formerly LEVEL 1 of DOD-D-1000.)

2.5.1.2 TPDTPD DI-SESS-81002D Developmental Design Drawings, Models and Associated Lists. These drawings, models and associated lists shall include, as applicable, parts lists, detail and assembly drawings, models, interface control data, logic diagrams, schematics, performance characteristics, critical manufacturing limits, and details of new materials and processes. Special inspection and test requirements necessary to determine compliance with requirements for the item shall be defined on the engineering drawings directly or by

reference. If required by the TDP Option Selection Worksheet, contract or purchase order, developmental design drawings, models and associated lists shall be prepared in accordance with ASME Y14.100 and the appropriate Appendices A thru E. (Formerly LEVEL 2 of DOD-D-1000.)

2.5.1.3 TPD DI-SESS-81000C Product Drawings, Models and Associated Lists. These selected engineering drawing types shall include: details of unique processes when they are essential to design and manufacturing; detailed performance ratings; dimensional and tolerance data; critical manufacturing assembly sequences; tolerance input and output parameters; schematics; mechanical and electrical connections; physical characteristics, including form and finishes; details of material identification; inspection, test and evaluation criteria; necessary calibration information and quality control data to enable the procurement or manufacture of an item essentially identical to the original item. Product drawings and associated lists shall be prepared in accordance with ASME Y14.100 and the appropriate Appendices A thru E in conjunction with ASME Y14.24, ASME Y14.34M and ASME Y14.35M, unless these requirements are not included in the TDP Options Worksheet, contract or purchase order. Models shall be prepared in accordance with MIL-DTL-31000C and ASME Y14.41. (Formerly Level 3 of DOD-D-1000.)

2.5.1.4 TPD DI-SESS-81003C Commercial Drawings, Models and Associated Lists. Commercial drawings, models and associated lists shall provide engineering and technical information in support of end products, or designated portions thereof, which are commercially developed items, commercial off-the-shelf items (COTS), or items not developed at government expense. These drawings, models and lists are prepared in accordance with the commercial design documentation practices of the contractor or supplier of the item.

2.5.1.5 TPD DI-SESS-81004C Special Inspection Equipment (SIE) Drawings, Models and Associated Lists. SIE drawings, models and associated lists shall be prepared to provide the data required to permit the limited production of SIE which duplicates the physical and performance characteristics of the original SIE. SIE is also

known as Special Test Equipment (STE).

2.5.1.6 TPD DI-SESS-81008C Special Tooling Drawings, Models and Associated Lists. Special tooling drawings, models and associated lists shall be prepared to provide the data required to manufacture special tooling which is mandatory to successfully produce the item. The special tooling shall be defined in detail to the extent necessary for a competent manufacturer to produce tooling which duplicates the performance characteristics of the original tooling.

2.5.1.7 Appropriate DID Listed for the Preparation of Military Specifications as Required in the Contract or Purchase Order. (See TABLE 2-6, Note 1.) These specifications shall be prepared as performance, detailed and program-unique specifications as required in the contract or purchase order. Included are fully coordinated, limited coordination or "USED IN LIEU OF" military specifications in accordance with MIL-STD-961.

2.5.1.7.1 Commercial Item Descriptions (CIDs). CIDs shall be prepared in accordance with Federal Standardization Manual to describe, by functional, performance, or essential physical requirements, available commercial products or services.

2.5.1.8 Appropriate DID Listed for the Preparation of Drawings, Models and Associated Lists for Preservation, Packaging, Packing and Marking Data. (See TABLE 2-3, Note 3.) Preservation, packaging, packing, and marking requirements for hardware shall be documented for each end item and repair accordance with MIL-STD-2073-1. Detailed drawings, models and associated lists required to describe packaging requirements shall be prepared as product or commercial drawings, models and associated lists whichever was ordered for the item under contract.

2.5.1.9 Appropriate DID Listed for the Documentation of Software. (See TABLE 2-3, Note 4) Software and software documentation required for the operation of the hardware defined in the TDP shall be prepared in accordance with MIL-DTL-31000C, IEEE 12207.0, IEEE 12207.1 and IEEE 12207.2. (Formerly MIL-STD-498.)

2.5.1.10 Special Packaging Instructions Drawings/Models. (New in MIL-DTL-31000C) Special packaging instructions drawings/models shall be prepared to provide the data required to manufacture special packaging which is mandatory to successfully produce and transport the item.

2.5.2 Conditions Required for Preparing Developmental and Production Drawings, Models and Associated Lists. The following conditions for the preparation of engineering drawings, models and associated lists for Development and Production shall be governed by the contract or purchase order citing the appropriate DIDs and “TDP Option Selection Worksheets”.

2.5.2.1 Application of the Metric System. When the metric system (SI) is specified in the contract or purchase order for new design, TDP documents shall be identified as metric documents and conform to FED-STD- 376.

2.5.2.1.1 Metric Values. Metric values, when used on engineering drawings, shall be in accordance with ASTM SI 10 (X-Ref: IEEE SI 10). (Formerly ASTM E 280.)

2.5.2.2 CAGE Assignment Number Placement. If a Government Design Activity or Contractor Design Activity is named, the Commercial and Government Entity (CAGE) code and drawing number will be placed in the title block of each engineering drawing and its associated list and on each model as defined in ASME Y14.41 and SECTION 26 of the DRM. References on existing documents or preprinted document forms using the terms “FSCM” or Code Ident.” need not be revised for the sole purpose of conversion to “CAGEC or “CAGE Code”. Such conversion may be made concurrently with other needed changes.

2.5.2.3 Design Activity Assignment Identification. When Government Design Activity drawing numbers are to be assigned, drawings must identify the assigning activity and if government drawing formats are to be supplied, drawings must identify the source.

2.5.2.4 Associated Lists. Specify the kinds of associated lists required.

2.5.2.5 Associated Lists Assembly Level. Specify the drawing assembly level at which associated lists will be prepared.

2.5.2.6 Selection of Drawing System. States whether the mono- or multi-detail drawing system will be used.

2.5.2.7 Placement of Parts Lists. Specify if parts lists shall be integral with, or separate from, the engineering drawing or model.

2.5.2.8 Drawing and Model Format. The number and types of drawings, models and associated lists should be kept to a minimum. As the complexity of the item increases, different types of engineering drawings providing additional engineering description and controls may be required by the procuring activity, contract or purchase order.

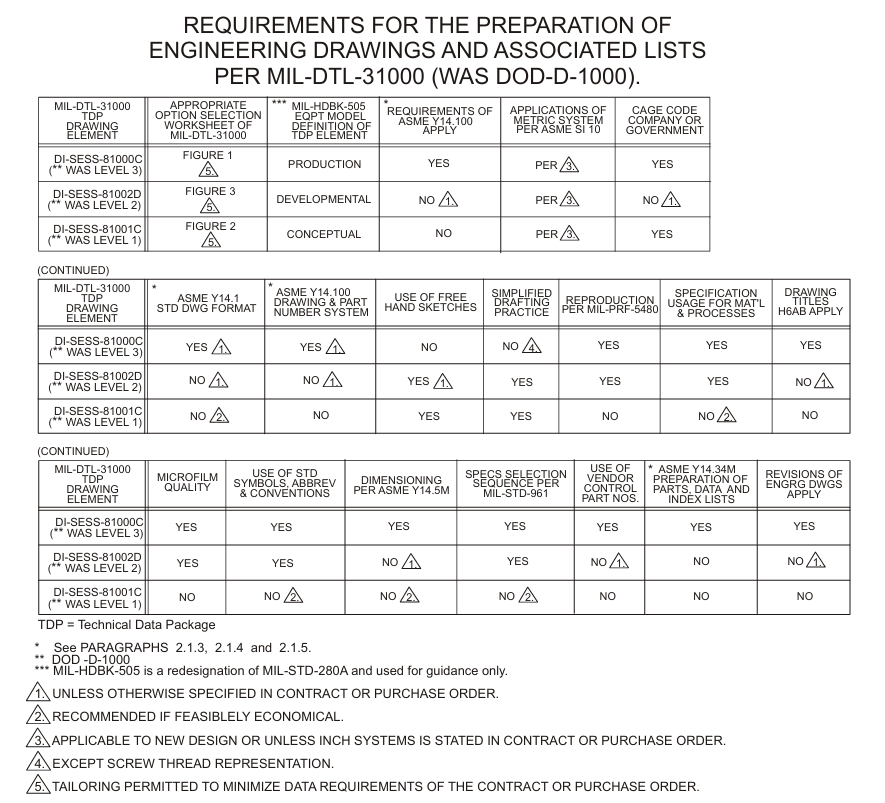

2.5.3 Technical Data Package (TDP) Drawings/Models in Relation to Previous Drawing Forms. Comparison of the current MIL-DTL-31000, the former MIL-T-31000, DOD-D-1000B (AM4) and the "NO" revision MIL-D-1000 (1965). (See TABLE 2-2.)

Table 2-2

2.5.4 Verifying the Use of TDP Drawing/Model Elements. Inspection of TDP Drawing/Model elements including TDP documents prepared by subcontractors, shall be inspected for the following:

- Compliance with the requirements of MIL-DTL-31000 and applicable Data Item Descriptions (DIDs) as tailored in the contract or purchase order.

- Inclusion of all documents, including sub-tier references, required to meet the information content requirements of the TDP element except Acquisition Streamlining and Standardization Information System (ASSIST Database) and Non-Government Standardization (NGS) documents.

- Accuracy of the assignment and identification of security markings, distribution statements, export control notices, rights-in-data legends and other special markings.

- Inclusion of contract numbers and contractor identifications.

- Legibility and reproducibility.

- TDP components have not been prepared for requirements which could be met by existing standardization documents except as permitted for commercial drawings, models and associated lists.

- References to other standardization documents, Government or non-Government, listed in the ASSIST DATABASE shall not be prepared or submitted as part of the TDP unless it is necessary to specify variations necessary to fulfill the design or performance requirements.

- Completeness and accuracy of the TDP documents, including required quality assurance information, in describing the design of the item, its subassemblies, and component parts. When the Government has approved, tested or accepted a configuration of the item that is the design to be described by the TDP documents.

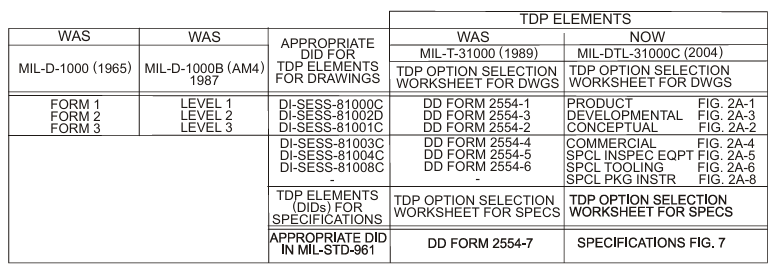

2.5.5 Technical Data Package (TDP) Elements for Drawings and Models with Reference to Supporting Documents. The contract or purchase order containing the Statement of Work (SOW) will cite the appropriate DIDs on the Contract Data Requirements List (CDRL) DD FORM 1423 (See APPENDIX A FIGURE 2A-9) for selecting TDP Elements for preparing drawings, models and specifications. Included will be the appropriate TDP Option Selection Worksheet, FIGURES 2A-1 through 2A-8a, for determining what technical data is being acquired. See TABLE 2-3.

2.5.6 Conditions Required for Preparing TDP Data Management Products. When specified in the contract or purchase order, the following data products related to the management and control of TDPs shall be prepared. Only the TDP data management products that are listed on the Contract Data Requirements List (CDRL), DD FORM 1423 of the contract or purchase order are required to be delivered to the Government.

2.5.6.1 Source Control Drawing Approval Request. Source Control Drawing (SOCD) approval requests shall be prepared and submitted to the cognizant Government activity specified in the contract or purchase order as having approval authority. Each potential source control item shall be approved by the Government activity having source control drawing approval authority prior to including of the source control drawing in the TDP.

2.5.6.2 Drawing Number Assignment Report. A drawing number assignment report shall be prepared to identify and describe the use of Government drawing numbers by the contractor per DI-SESS-81011C.

2.5.6.3 Proposed Critical Manufacturing Process Description. Proposed critical manufacturing process descriptions shall be prepared to describe manufacturing processes which are critical to meeting the design requirements of the item per DI-SESS-81012C. The process shall be approved as critical by the Government activity cited in the contract or purchase order as having approval authority before it is designated as mandatory in TDP documents.

2.5.7 Verifying the Use of TDP Data Management Products. Inspection of TDP Data Management Products and the components thereof, including documents prepared by subcontractors, shall be inspected for the following:

- Compliance with the requirements of MIL-DTL-31000 and applicable Data Item Descriptions (DIDs) as tailored in the contract or purchase order.

- Inclusion of all documents, including sub-tier references, required to meet the information disclosure requirements of the TDP Data Management Product.

- Accuracy of the assignment and identification of security markings, distribution statements, export control notices, right-in-data legends, and other special markings.

- Inclusion of contract numbers and contractor identifications, when applicable.

- Legibility and reproducibility.

2.5.8 Technical Data Package (TDP) Data Management Products with Reference to Supporting Documents The contract or purchase order containing the Statement of Work (SOW) will cite the appropriate DIDs on the Contract Data Requirements List (CDRL). (DD FORM 1423) (See APPENDIX A FIGURE 2A-9) for selecting TDP Management Data Products for preparing what types of data is being acquired. (See TABLE 2-4.)

NOTE: Unless otherwise specified, Technical Data Package (TDP) Data Management Products require “DISTRIBUTION STATEMENT” notations applied to the document.

Table 2-4

2.6 RESPONSIBILITIES OF ENGINEERING DRAWING MANAGEMENT RELATED FUNCTIONS.

2.6.1 Program Management.

2.6.1.1 Drawing and Data Management Products Requirements. Program management is responsible for informing applicable documentation activities of the requirements that drawings and Data Management Products must meet. These requirements are defined by the Program Directive, Work Statement, Statement of Work (SOW) Work Orders, etc. TABLE 2-1 lists the requirements for each of the drawing disclosure levels and technical data documentation. TDPs, except conceptual design and developmental design drawings, shall define the physical and functional characteristics of the approved, tested, and accepted configuration of the item and its subordinate assemblies, and parts thereof. These requirements apply to data prepared by either manual or automated methods, such as Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) systems, or combinations thereof. Furthermore, these requirements apply to data using U.S. customary units, the International System of Units (SI), or combination thereof.

2.6.2 Preparation and Management.

2.6.2.1 Use of Government and non-Government standardization documents. TDP documents shall not be prepared or submitted to indicate1 document requirements which are defined by existing Government or non-Government standardization documents of the United States or international standardization documents listed in the ASSIST DATABASE or from the societies governing the documents (such as the American Society of Mechanical Engineers (ASME)). These requirements shall be specified by reference to the appropriate standardization document. When the requirements in such standardization documents do not completely fulfill the design or performance requirements of an item, TDP documents for the item may invoke the requirements of the standardization document and specify the variations necessary to fulfill the design or performance requirements.

Note: MIL-DTL-31000C corrected a typo in clause 3.2.1 of MIL-DTL-31000B, which is the source for paragraph 2.6.2.1 above. The word “indicate” was omitted in MIL-DTL-31000A and MIL-DTL-31000B, thus the sentence stated that existing standardization documents were not to be used in the preparation of a TDP. This omission in MIL-DTL-31000B reversed the meaning of this sentence and was incorrect; the corrected material in paragraph 2.6.2.1 reflects the actual requirement.

The purpose and intent of clause 3.2.1 in MIL-DTL-31000 is to clarify that approved existing standards (such as those listed in the ASSIST Database) must be used in the preparation of a TDP.

2.6.2.2 Use of International and Foreign Standardization Documents. International Standardization Organization / International Electrotechnical Commission (ISO/IEC) standardization documents adopted by the American National Standards Institute (ANSI) for use in the United States may be used to define requirements on TDP documents. National standardization documents of foreign countries and European Standards (NORMEs) (EN) shall not be used without the approval of the Government procuring activity. The use of international and foreign standardization documents in multinational programs subject to memorandum of understanding between governments shall be governed by the terms of that agreement.

2.6.2.3 Reference Documents. Except as specified in PARAGRAPH 2.6.2.4, documents referenced in a TDP element shall be furnished as an integral part of that element, when essential to meet the information content requirements of the TDP element. Technical manuals, procedural manuals, maintenance manuals, company drafting manuals and management plans shall not be considered as referenced documents. When information essential to meeting the information content requirements of a TDP element (such as default surface texture values) are contained in such documents, that information shall be delineated on the applicable TDP document or incorporated in a document acceptable for inclusion in the TDP element.

2.6.2.4 Existing Data. When existing data meets the following criteria, or can be modified or revised to meet the following criteria, it shall be used in lieu of preparing new data:

- It is furnished with rights-in-data consistent with the contract stipulations regarding data rights.

- It is furnished at a cost to the Government equal to or less than the cost of preparing new data.

- It meets the legibility and reproducibility requirements for the TDP element of which it is to be a part.

- It meets the information content requirements of the TDP of which it is to be a part.

- It is identified by a Commercial and Government Entity (CAGE) Code, document number, title, and applicable contract number(s).

- Any nonstandard symbols, drawing or documentation practices used are explained in the document or in a document referenced on the document containing the nonstandard symbol or practice.

- It meets the language and clarity requirements. See PARAGRAPHS 2.1.1.1 and 2.6.2.7.

- Any revisions to the existing data are made in accordance with one of the following:

- The revisions are made using the same preparation guidelines as were used in preparing the existing data, or

- All existing characteristics of the existing data are updated to the new preparation guidelines used in making the revisions.

2.6.2.5 Company Standards. When the use of company standards is permitted by the contract or purchase order, company standards shall meet the requirements of PARAGRAPH 2.6.2.4 for existing data plus the following:

- If the company standard defines a vendor item, the standard shall provide the same information as a Vendor Item Control Drawing (VICD) for the identification and procurement of an interchangeable item, and

- All documents referenced in the standard shall be supplied as required by PARAGRAPHS 2.6.2.1, 2.6.2.2 and 2.6.2.3, and shall meet the same requirements as a company standard.

2.6.2.6 Commercial Drawings Exempted. Commercial drawings and associated lists are exempt from the requirements of PARAGRAPHS 2.6.2.4 and 2.6.2.5.

2.6.2.7 Language and Clarity. Unless otherwise specified by a multinational agreement, TDP documents shall be in the English language. People knowledgeable in the subject matter presented shall delineate requirements, including explanations of non-standard practices or symbols, clearly, concisely, and without ambiguity so that their correct interpretation is readily discernible.

2.6.2.8 Automated Document Presentation. TDP documentation, regardless of the method of preparation (for example computer, plotter, or photosetter), shall satisfy the format and content requirements of specifications and standards controlling those documents as invoked and tailored in the contract or purchase order. Hard copy deliverable of such documents shall be human readable without additional interpretation. Digital deliverables shall be human readable when processed by appropriate digital interpretation programs. Variations from the controlling specifications and standards that do not adversely affect the legibility and reproducibility of deliverable media, or the integrity of the data content are permitted, unless otherwise prohibited by the contract or purchase order.

2.6.2.9 Database Access. When electronic, on-line access to contractor generated data is preferred to actual delivery of hard copy data, such access shall be through a Contractor Integrated Technical Information Service (CTIS) and the contractual application of MIL-STD-974 or commercial equivalent.

2.6.3 Protecting Classified Information. TDPs or parts thereof, containing classified information shall be protected and marked in accordance with the Department of Defense Industrial Security Manual for Safeguarding Classified Information (DoD 5220.22-M). When 3D TDP data is used, the solid models shall display classification marking clearly visible when the solid model is first opened.

2.6.4 Distribution Statements. All TDP documents prepared by or for the DoD will cite the appropriate distribution statement, and if applicable, export control notice, in accordance with DoD D 5230.24.

2.6.5 Contract Numbers and Contractor Identification. When required by the contract, purchase order or applicable Data Item Description (DID), TDP documents shall identify the contractor and contract number under which is prepared or delivered, or both.

2.6.5.1 Application of Contract Numbers and Contractor Identification. When contract numbers and contractor identifications are required on TDP documents, they shall be applied to document originals. The contract numbers shall meet the legibility and reproducibility requirements applicable to the document and be within the prescribed borders or margins of the document.

2.6.5.2 Contract Numbers in Data Rights Legends. The requirements of PARAGRAPHS 2.6.5 and 2.6.5.1 do not alter current Defense Federal Acquisition Regulation Supplement (DFARS) requirements for identifying contractors and prime contract numbers in rights-in-data legends. Furthermore, contractor identifications and contract numbers in rights-in-data legends do not satisfy the requirements of PARAGRAPHS 2.6.5 and 2.6.5.1.

2.6.6 Tailoring Of Specification (MIL-DTL-31000) Consideration. Program management shall work closely with the procuring activity in applying "Tailoring of the Specification" approach for providing the Government with the minimum essential engineering drawings and associated lists to satisfy a particular procurement. Consideration should be given to the following:

- Identification of the equipment model as defined in MIL-HDBK-505. See TABLE 2-1.

- Drawing selection as applicable in the preparation of drawings. See TABLE 2-1.

- Acquisition of engineering drawings and associated lists to support use of the equipment. For example:

- Exploratory or advance models do not require delivery of engineering drawing when design evaluation or interface drawings to evaluate interrelated systems are adequate for delivery. Referred to as Conceptual Design Drawings.

- If procurement is an engineering development model(s), drawings to support installation, operation and maintenance should be adequate. Referred to as Developmental Design Drawings.

- Drawings to enable procurement and logistic support of the equipment without additional design recourse to the original design activity are generally required only for production programs. Referred to as Product Drawings.

2.6.6.1 Application of Tailoring. The Contract, Purchase Order (PO) or Statement Of Work (SOW) shall be reviewed to the extent of the performance requirements to determine if "tailoring" can be expressed on the contract to impose that only the minimum essential needs be met to produce the item. Use the appropriate of TDP tailoring sheets (FIGURES 2A-1 through 2A-8a) TDP Option Selection Worksheets block "OTHER TAILORING" provided by the contract or purchase order to accomplish this task.

2.6.6.2 Responsibility for The Tailoring of The Specification(s). While tailoring is primarily the responsibility of the procuring agency (government/military) it is none the less the responsibility of program management to accept, concur, reject or negotiate each requirement prior to acceptance of a contract or purchase order requiring engineering drawings and associated lists. TABLE 2-5 identifies these requirements, and also provides comments relating to conditions which should be considered for effective application and tailoring of the specifications. TABLE 2-5 has been updated from its previous use with DOD-D-1000 and MIL-T-31000 to reflect its use with MIL-DTL-31000. Furthermore, Technical Data Package (TDP) elements requirements may be tailored by the contractor in response to a solicitation using the guidelines of MIL-HDBK-248. The results of all tailoring must be incorporated into the contract or purchase order.

2.6.6.3 Contractor Management of Technical Data Package (TDP) Elements. Prime contractors are not only responsible for reviewing any tailoring of the specifications by the procuring agency but are also responsible for preparing and managing TDPs of their own. This includes ensuring that TDPs and component parts thereof for items acquired from subcontractors and their lower-tier subcontractors meet the requirements of the government contract or purchase order.

2.6.6.4 Contractor Identification on TDP documents. When a TDP document is prepared under a Government contract, the Government contract number under which it is prepared shall appear on the first sheet of the document original. When a TDP document is delivered under a Government contract other than the one under which it was prepared, the Government contract number under which it is delivered shall appear on the first sheet of each copy submitted. If the document is prepared and submitted under the same contract, only the entry for the contract under which it is prepared is required. When a TDP document is prepared by a design activity other than the one represented by the CAGE Code assigned to the document, that design activity shall be identified on the document by its CAGE Code or name and the applicable contract numbers. Subcontractors preparing TDP documents shall be identified by CAGE Code or name and subcontract numbers to establish traceability to the applicable Government contract. When TDP documents or copies are to be delivered under a subsequent or other contract, apply contract numbers by using a rubber stamp (or equivalent) for paper copies, photographic overlays (or equivalent) for microfilm, or electronic application for digital data.

2.6.6.5 Technical Data Package (TDP). TDPs prepared in accordance with MIL-DTL-31000 shall contain engineering information sufficient for design evaluation or procurement of substantially identical items without additional design effort. If an item has been developed with no expense to the Government and/or unlimited rights in-data have not been acquired, a TDP shall be prepared for the item which is adequate for procurement of the same item from the manufacturer. Additionally, the item must be functionally and physically interchangeable with items from other sources if other sources for a functionally and physically interchangeable item exist.

2.6.6.5.1 Requirement for a Technical Data Package (TDP). If a procuring agency (government/military) determines that they need technical data for the immediate planned or probable future use of a system or material, a TDP shall be prepared in accordance with MIL-DTL-31000 and include the appropriate DIDs for the level of disclosure for drawings, models, associated lists, data, and selection worksheets (See TABLE 2-6 and APPENDIX A). Appropriate FIGURES 1 through 8a from MIL-DTL-31000 shall be included in the contract or purchase order. See FIGURES 2A-1 through 2A-8a for copies of the TDP Options Selections Worksheets.

=INSERT TABLES=

2.6.6.5.2 Grouping of Related Documents Required for Preparing a Technical Data Package (TDP). A TDP shall be prepared in accordance with MIL-DTL-31000C. The prime contractor shall levy the same contract requirements for the TDP on the subcontractor as those levied by the Government on the prime contractor. Drawings and associated lists shall be selected from the following:

- Conceptual Design Drawings/Models. Conceptual design drawings/models shall be in accordance with MIL-DTL-31000C, the detail requirements of DI-SESS-81001C and FIGURES 2 and 2a. See TABLE 2-6 and APPENDIX A, FIGURES 2A-2 and 2A-2a.

- Developmental Design Drawings/Models. Development design drawings/models shall be in accordance with MIL-DTL-31000C, the detail requirements of DI-SESS-81002D and FIGURES 3 and 3a. See TABLE 2-6 and APPENDIX A, FIGURES 2A-3 and 2A-3a.

- Product Drawings/Models. Product drawings/models shall be in accordance with MIL-DTL-31000C, the detail requirements of DI-SESS-81000C and FIGURES 1 and 1a. See TABLE 2-6 and APPENDIX A, FIGURES 2A-1 and 2A-1a.

- Commercial Drawings/Models. Commercial drawings/models shall be in accordance with MIL-DTL-31000C, the detail requirements of DI-SESS-81003C and FIGURE 4. See TABLE 2-6 and APPENDIX A, FIGURE 2A-4.

- Special Inspection Equipment Drawings/Models (SIE). Special inspection drawings/models shall be in accordance with MIL-DTL-31000C, the detail requirements of DI-SESS-81004C and FIGURES 5 and 5a. See TABLE 2-6 and APPENDIX A, FIGURES 2A-5 and 2A-5a.

- Special Tooling Drawings. Special tooling drawings/models shall be prepared in accordance with MIL-DTL-31000C, the detail requirements of DI-SESS-81008C and FIGURES 6 and 6a. See TABLE 2-6 and APPENDIX A, FIGURES 2A-6 and 2A-6a.

- Specifications. Specifications shall be prepared in accordance with MIL-DTL-31000C and the detail requirements of applicable DIDS in MIL-STD-961 and FIGURE 7. See TABLE 2-6 and APPENDIX A FIGURE 2A-7.

- Special Packaging Instructions Drawings/Models. Special tooling drawings/models shall be prepared in accordance with MIL-DTL-31000C and FIGURES 8 and 8a. See TABLE 2-6 and APPENDIX A, FIGURES 2A-8 and 2A-8a.

2.6.7 Contractual Interpretation of Frequently Used Common Words and Phrases on Drawings/Specifications.

- Referenced documents on drawings/specifications shall be cited by only one of the following methods throughout the drawing:

- "per --------"

- "conforming to ------------"

- "as specified in ----------------"

- "in accordance with ------------------" or "IAW"

- "Unless otherwise specified.” This phrase, when used, shall always precede the beginning of the note or sentence that makes the requirement. This phrase shall be used only when it is possible to clarify its meaning by providing a reference on the drawing or to another document that clearly specifies the exceptions.

2.6.8 Contract Binding or Non-binding Words.